Visually inspect No.2 ECU for correct assembly and condition

Work continued this week:

XZ179:

- Visually inspect No.2 ECU for correct assembly and condition in preparation for ground run.

- Visually inspect No.2 ECU bay for presence of FOD and cleanliness in preparation for ground run, any debris cleaned/removed as required.

- Inspect No.2 ECU/ECU bay for any static leaks that may have developed – nil found.

- Ensure No.2 ECU oil level is correct in preparation for ground run.

- Lubricate tail rotor hub in preparation for No.2 ECU ground runs.

- Lubricate tail rotor driveshaft bearings in preparation for No.2 ECU ground runs.

- Carry out an inventory/assessment of blade folding kit in our possession, make up a complete kit and trial fold blades to right hand side of aircraft.

- Manufacture torquemeter system test cables.

- Continue testing/fault finding of torquemeter system.

- Fire bottle system crossfeed system switch arrived.

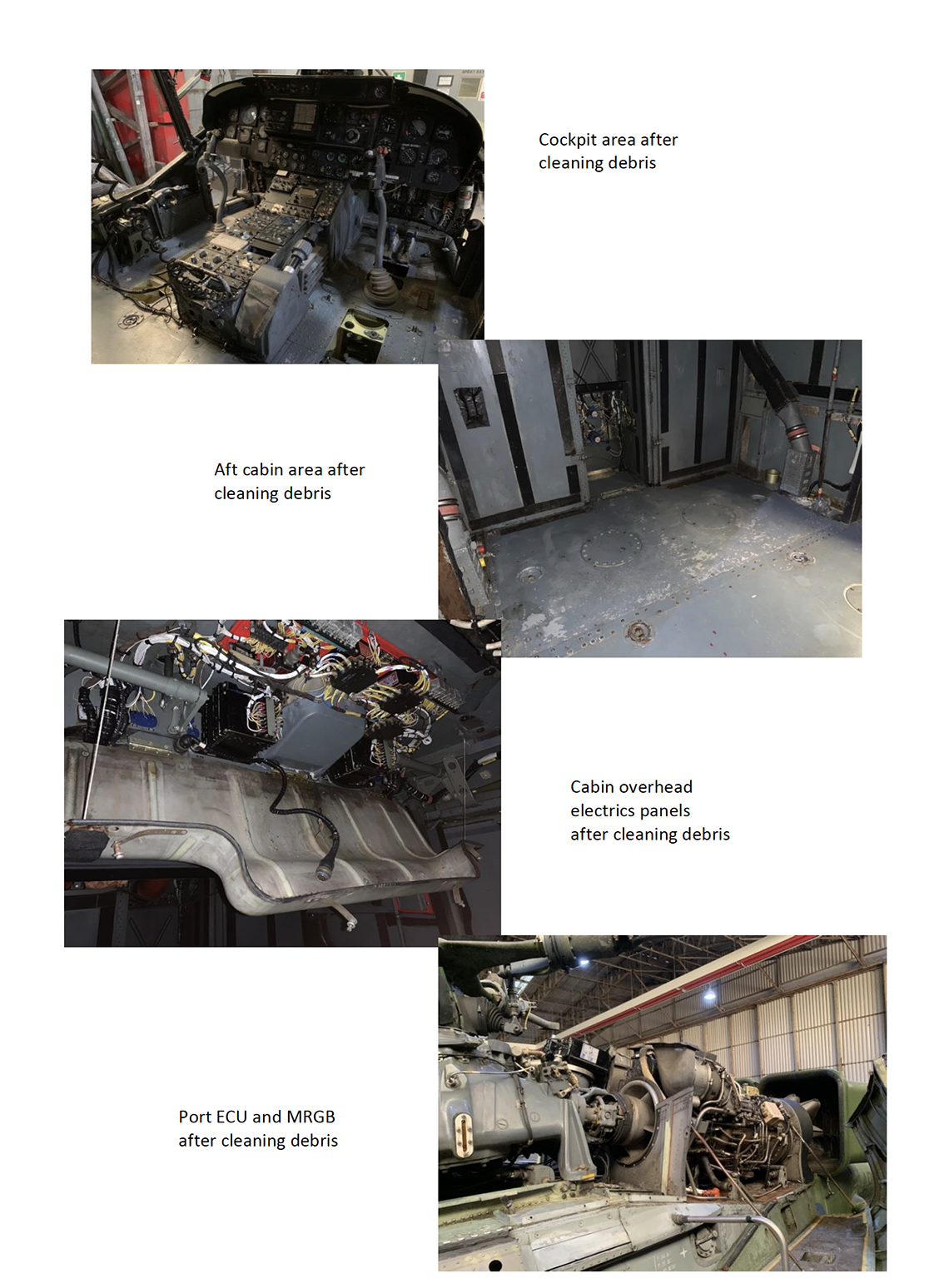

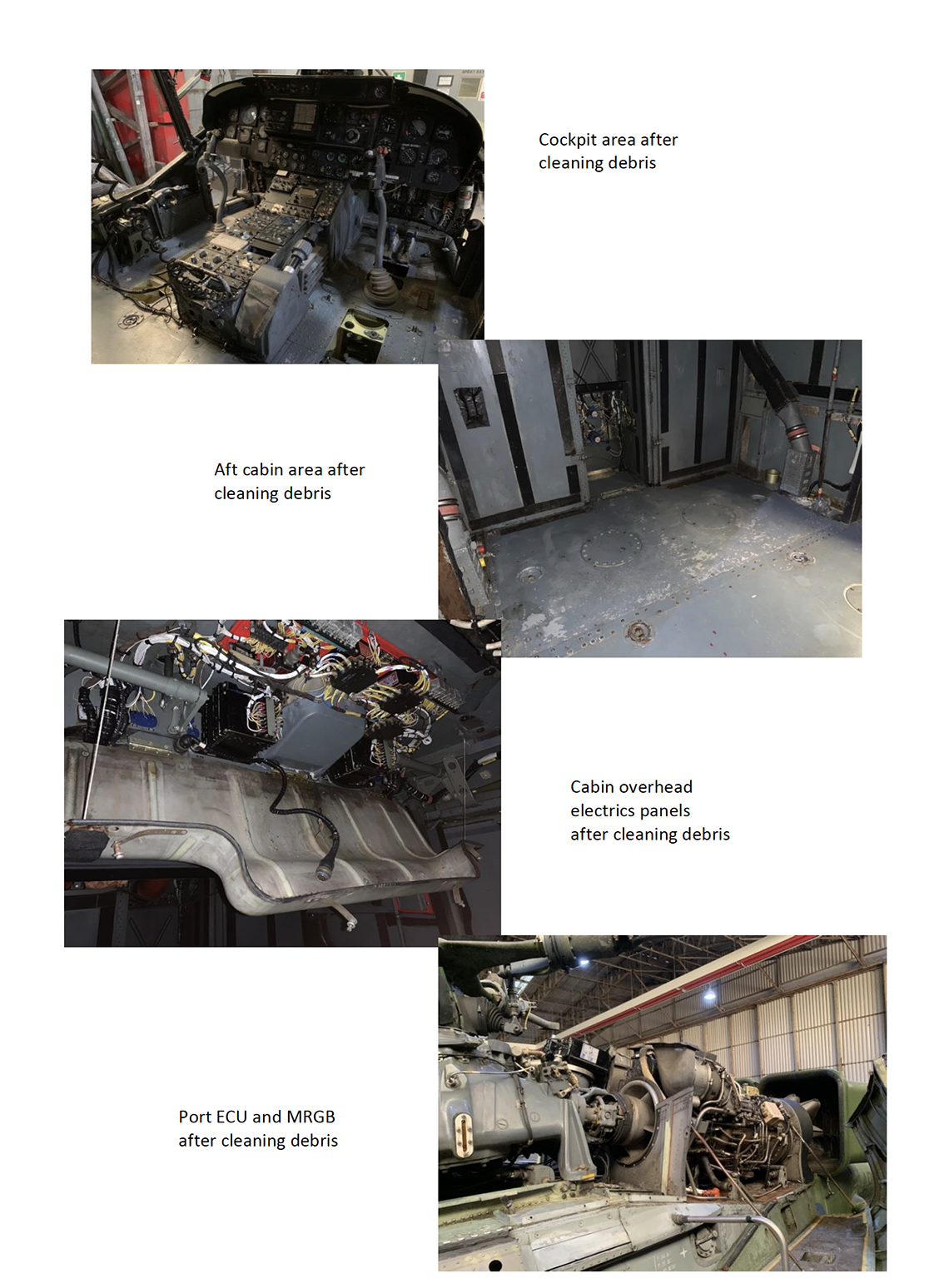

XZ678:

- Airframe and cabin cleared as far as possible of debris.

- Begun inventory of any components removed to allow access.

- Begun inventory of rotable components for life span and condition assessment.

Work to be continued next week:

XZ179:

- Continue investigation of No.1 torquemeter system fault.

- Fit newly arrived fire bottle crossfeed switch.

- Fully re-test fire bottle system post fit of switch.

- Ensure all paperwork is satisfactory in anticipation of CAA visit.

XZ678:

- Continue investigation of rotables for remaining life span/condition.

- Continue inventory of components removed.

twentytwopl 2 November 2021 Uncategorised