• No.1 engine bay fitted with new aluminium tape and sealed with RTV – components have begun to be refitted, still on going

• No.2 engine fitted with new aluminium tape and all available components have been refitted – waiting on a bracket to support a cabin hot air take off valve – still on going

• ECU and ECU bay inspections have been carried out, the MOD state has been determined and the missing component required has been ordered.

• Forward fuel tank pump has been wired up correctly and repaired after being found damaged during checks for continuity

• All fuel tanks have been cleaned and hovered again after previous work to ensure no FOD.

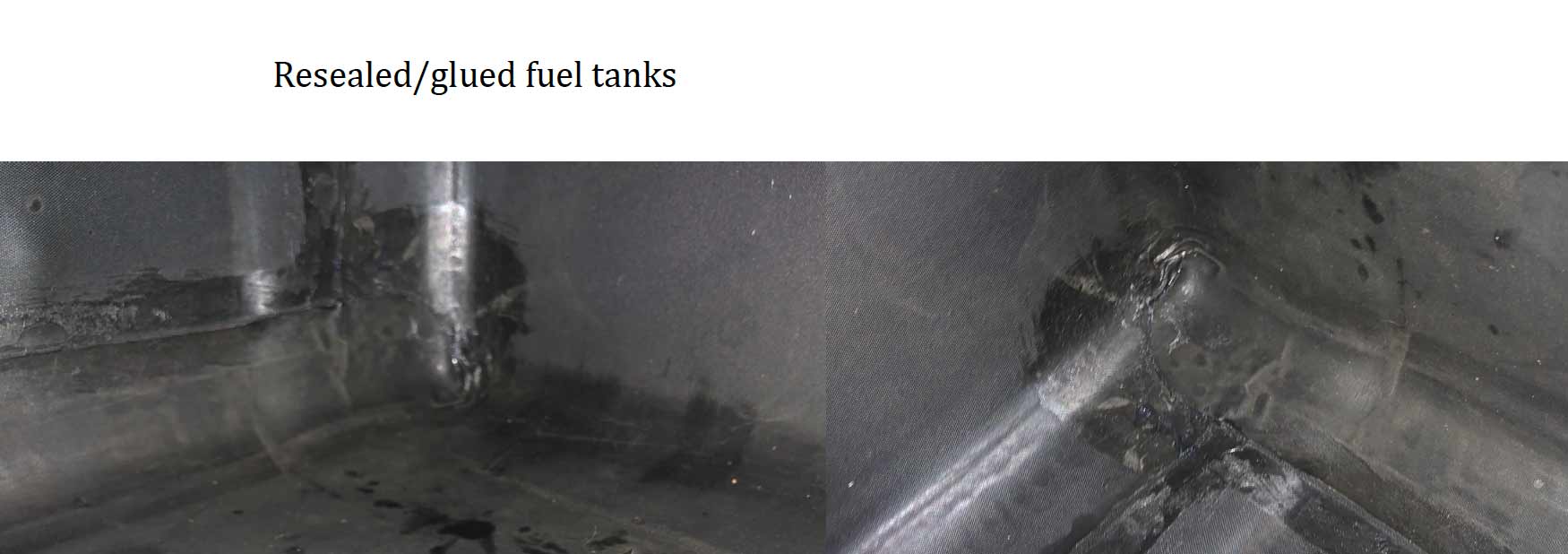

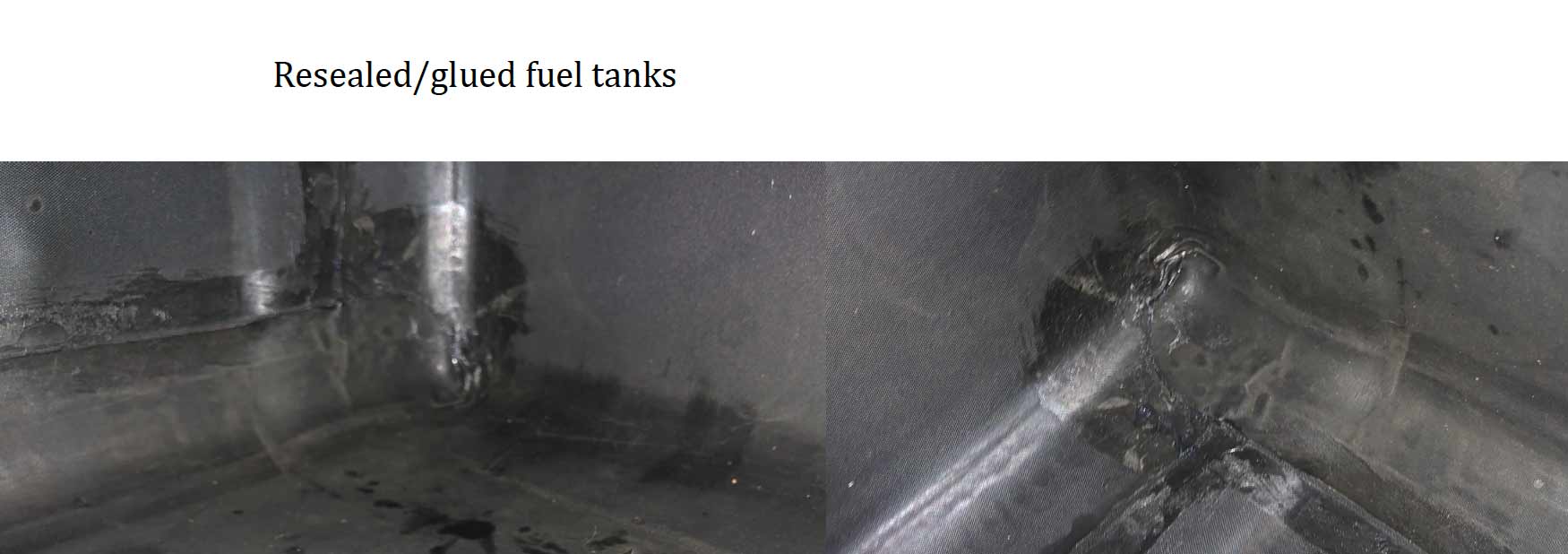

• 8 points in various tanks have been resealed/glued where edges and corners have started to lift – most likely due to the change in temperatures recently combined with not having fuel in the tanks.

• Research into MOD state of bolts required for fuel tank lids carried out and AGS ordered.

• Bracket and P-clip required for holding a pipe in port collector tank has been manufactured and fitted.

• Various fuel tank pipes have been reconnected after MOD 0821 has been incorporated.

• Dressing of MRGB has continued – certain extra control arm mounts are required from old gearbox, which is extending the build up time.

• Lateral control servo has been fitted to new MRGB along with No.2 hydraulic system pressure and return lines

• Continue dressing MRGB – focusing on fitting the two new servos

• Test fuel tanks by partially filling tanks with fuel to discover any potential leaks with the drain seals and bottom panels – could not be carried out due to tanks being resealed/glued

• Fit fire retardant seal between engine bays if we receive it from Pat

twentytwopl 7 May 2020 Uncategorised